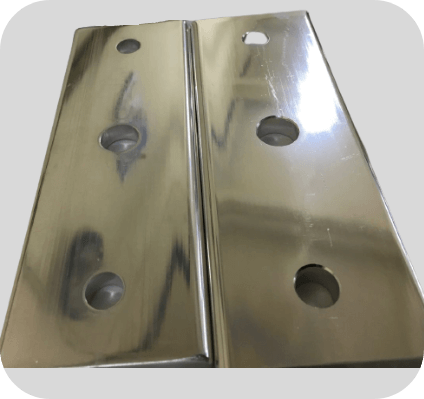

Tin is a white or silvery metal with a respectable level of corrosion resistance. Tin plating is the technique of using an electrical current to apply a layer of solderable tin on a material’s surface. Materials including steel, stainless steel, copper, and copper alloys can all have tin plating. It may be incredibly economical because tin is significantly more affordable and widely accessible than precious metals like gold, platinum, or palladium.

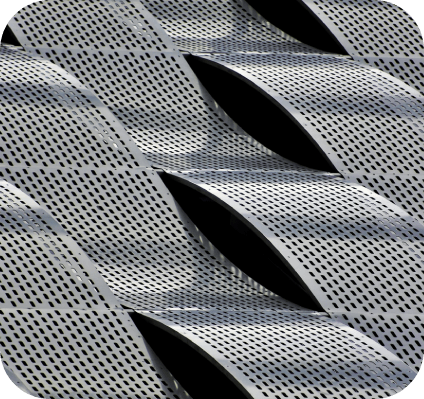

It is a typical coating for equipment used in the food processing industry due to its non-toxic qualities. Because of its excellent solderability and low melting point, tin plating is used in various industries, including the aerospace and automotive sectors.

Tin is a popular choice for sectors associated with food service, particularly in manufacturing fast food equipment and kitchenware, due to its ductility, non-toxic makeup, and corrosion resistance. It is also widely used in electronics because it keeps solderability intact.

Tin plating has played a sizable role in the housing sector as interest in solar energy continues to grow. It can enhance the anti-galling qualities of metal items’ surfaces. Many nonferrous and ferrous surfaces are protected utilizing the tin plate method. Electrical contacts, connectors, switches, relays, circuitry, machine parts, and similar products are frequently produced using tin plating.

Based on the base material, tin is applied as a metal plating to maintain or improve adhesion strength. Due to its capacity to shield the base metal from oxidation and corrosion, tin plating is also frequently used in electronics. The FDA also permits tin for use in the food industry.

Other advantages of Tin plating include:

- Cost-effective

- Excellent contact resistance

- Outstanding solderability

- Incredibly effective at protecting

- Non-toxic

Tin is affordable and frequently used to give copper a first coat. We have created and mastered a cost-efficient tin plating method over decades that can be adjusted to meet your unique operational needs.

To find out more about our Tin Plating procedure and how it can be customized for your business, contact us right now!!

Standards Followed In FMC

ASTM B545 – Electrodeposited Coatings of Tin.